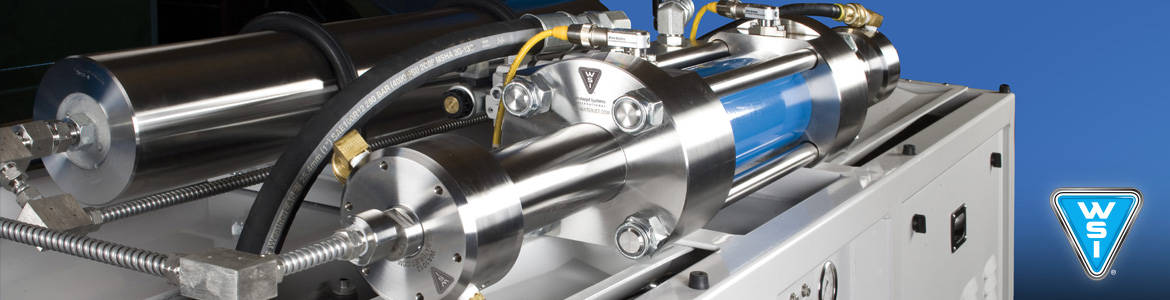

With design features that provide performance and reliability unmatched by the waterjet-cutting competition, WSI’s patented intensifier technology is among the most advanced in the world.

No other waterjet manufacturer can offer the critical enhancements of WSI’s patented technology—like our Dura-Check Replaceable Seat Check Valve Assembly on both inlet and outlet ends. This isolates the valuable check valve body from contact with moving parts, meaning worry-free operation and the longest running life available.

If you have a surface or materials that need cutting, then one of WSI’s varied ultra-high pressure and performance waterjet cutting pumps are industrially proven to power the job. No matter the size of your business, or model of WSI pump needed, all of WSI’s waterjet cutting pumps are built with WSI’s patented intensifier technology.

Since the Postwar Era, the evolution of waterjet cutting technology has thrust waterjets to the forefront of the machining tool cutters—with waterjet cutting being credited for providing reliability, versatility, control and the ultimate in cutting accuracy.

WSI Waterjet Cutting Pumps cut a variety of products: food, metal, glass, stone, and tile—even paper. WSI also services a wide range of customers from Automotive Industry Giants, to the finest Italian Granite Slab Fabricators, all the way down to the Solo Artist who wishes to meticulously cut and create unique works.

The utilization of an abrasive combined with ultra-high pressurized water produces waterjet cutting power without the heat associated with other cutting methods. The properties and structure of the materials being cut are not altered or compromised because of the lack of heat produced with waterjet cutting.

And in the age of “Going Green,” waterjet cutting is known as a “Green Technology” for its lack of output disposal and non-hazardous material waste.