With numerous waterjet suppliers in the market, it can be a daunting task to determine which ones are reputable and offer consistent, high-performing products. Complicating matters, many waterjet suppliers do not manufacture their own products, relying instead on sourcing components from various suppliers and merging them together. This practice often results in unpredictable and inconsistent quality.

In this blog, we delve into the challenge of qualifying a good waterjet supplier and provide insights on how to navigate this landscape to ensure consistent and superior waterjet pumps and spare parts.

Deciphering Supplier Claims

To appear as if they manufacture their own high-pressure products, some suppliers employ tactics such as emphasizing their parts are manufactured in the same country where the company is located. Others make statements like the parts and systems are “assembled,” “engineered,” “developed,” or “designed” by the company. Some claim to have a “manufacturing proficiency” without explicitly stating they manufacture the parts themselves. These claims can be misleading, making it vital to dig deeper and uncover the truth.

Lack of Visual Evidence

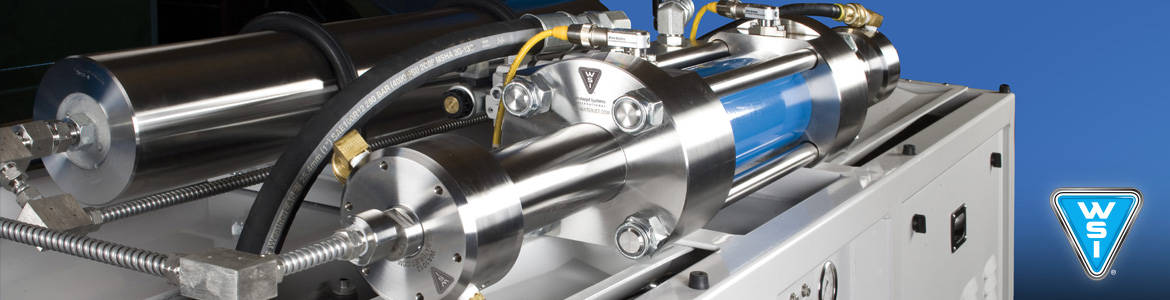

Another red flag is the absence of videos or pictures showcasing the machines used to manufacture their waterjet parts. Reputable manufacturers often take pride in displaying their production facilities and processes. If a supplier fails to provide visual evidence of their manufacturing capabilities, it raises questions about their level of expertise and the source of their waterjet cutting pumps and components.

The Importance of Inquiring

When qualifying a waterjet supplier, it is crucial to ask specific questions about their manufacturing process and the origin of their parts. Inquire whether they manufacture their parts within their facility or if they source them from external suppliers. Ask if they manufacture the most difficult to make high pressure components, such as high-pressure waterjet cylinders and high-pressure check valve bodies. Some companies will make only products that are made of solid materials and do not require the specialized processing the most demanding parts require. This information is crucial in understanding the level of knowledge, processing, and expertise behind their production, as well as the reliability and performance of their parts and their company.

Emphasizing Manufacturing Expertise

While some suppliers may claim to be “waterjet engineering experts,” it is important to scrutinize their actual manufacturing capabilities. True expertise lies not only in engineering, but also in the ability to manufacture high-quality parts consistently. In house manufacturing allows the producer to scrutinize and make adjustments to parts as they are being made, instead of making compromises when shipments from an outside vendor arrive and are not with specification. Look for suppliers who can demonstrate their manufacturing prowess and provide evidence of their in-house production capabilities.

Assessing Stability and Reputation

A stable and reputable supplier is more likely to provide consistent and good performing products. Look for suppliers with a long-standing presence in the industry and a track record of delivering reliable waterjet solutions. Seek customer testimonials, reviews, and references to gauge their reputation and customer satisfaction levels.

Unveiling the Extent of Manufacturing

Even if a company can demonstrate they manufacture some of their products, it is essential to inquire about the specific portion or percentage they produce in-house. Some suppliers may only manufacture a small fraction of their product lineup while relying heavily on external sources for the rest. By understanding the extent of their manufacturing capabilities, you can gauge the level of control they have over the entire product range.

Assessing Quality Control

Manufacturing expertise goes hand in hand with stringent quality control measures. When qualifying a supplier, inquire about their quality control processes throughout the manufacturing journey. In-house manufacturing allows control of the quality and manufacturing process, from the qualification of raw material suppliers all the way to choosing the type of packaging that will best protect the product for shipment. Reliable suppliers will have robust quality control protocols in place for all aspects of the product evolution, including inspections, testing, and certifications. This ensures that each component meets the necessary standards for consistent and reliable performance.

Stability and Supply Chain Management

A stable waterjet manufacturer with a well-managed supply chain is more likely to offer consistent and good-performing waterjet products. Inquire about the stability of their supply chain and the relationships they have with their raw material and component suppliers. Also inquire about the amount of safety stock they maintain. An appropriate safety stock contributes to a consistent product, as the manufacturer will not need to rely on unproven or subpar providers in the event of supplier material shortages.

Prioritizing Long-Term Partnerships

When searching for a waterjet supplier, it is beneficial to focus on establishing long-term partnerships, rather than short-term transactions. Reliable suppliers are invested in your success and strive to meet your evolving needs. Look for suppliers who prioritize building strong relationships, providing ongoing waterjet technical support, and continuously improving their products, and waterjet service personnel and technicians who support them.

Striking the Right Balance – Price Versus Performance

Instead of fixating solely on the lowest price, it is prudent to strike the right balance between cost and performance.

The middle quotation often represents the optimal mix of savings and quality. Reputable suppliers held to higher standards and serving discerning customers understand the value of maintaining the required quality level. They invest in robust manufacturing processes, rigorous quality control, and continuous improvement initiatives, which may translate into slightly higher pricing. However, the long-term benefits of reliability, extended product life, and reduced operational issues outweigh the initial cost savings.

Transparent Communication and Waterjet Technical Support

A good waterjet supplier will be transparent in their communication and provide clear documentation about their product specifications, their location, and whom you should contact should you require assistance.

They should readily address your questions and concerns and provide detailed information to support their claims. Do not be afraid to ask how many technicians the company employs, their average years of waterjet experience, and the necessary notification-to-departure time for a technician should a problem arise. Although usually a given, we also recommend you confirm that technical assistance by e-mail and phone is always free of charge.

Transparent communication and support is a sign of a trustworthy supplier who values open and honest collaboration.

Summary

Qualifying a good waterjet supplier with consistent and good-performing products requires careful evaluation and scrutiny. Even if a supplier claims to manufacture their own products, it is crucial to inquire about the extent of their manufacturing capabilities. Assessing their quality control measures, stability, and supply chain management are equally important factors. By prioritizing long-term partnerships, seeking references, and valuing transparent communication, you can select a reliable supplier that delivers the consistent and high-quality waterjet products your business needs for success.

About the Author

Waterjet Systems International has been a manufacturer of premium high-pressure and ultra high-pressure waterjet pumps and replacement parts for over 30 years. WSI manufactures its own line of proprietary waterjet pumps and cutting heads along with a premium line of KMT Waterjet, Flow Waterjet, and H2OJet compatible replacement parts. WSI specializes in servicing the worldwide automotive and aerospace industries, but prides itself in providing the highest level of support, service, and products to its OEM’s, distributors, and end users regardless of size, industry, or purchasing power.